Ecommerce inventory is difficult to manage, especially when you have grown your business to the point where you are selling on multiple sales channels, shipping orders internationally, and storing products in multiple locations. The order fulfillment process is one of the biggest challenges that business owners face when trying to manage their online orders and inventory levels.

In this guide, I’ll explain how the order fulfillment process affects your inventory management and some best practices you can use to improve your process.

What Is Order Fulfillment?

Order fulfillment is the process of the customer ordering, receiving, and (unfortunately!) returning a product they buy from an ecommerce store. It also includes all the steps in between, including storing inventory, warehousing, inventory management, shipping, and order tracking.

Depending on your business model and the size of your online store, some of these processes will be handled “in-house,” while some will be outsourced. Nearly all companies will outsource the last-mile delivery, but many will also outsource warehousing to a 3PL (Third Party Logistics fulfillment center) and use third-party fulfillment software.

Some order fulfillment software is a blend of in-house control and outsourcing. Pick the solution that's best for you.

What Are The Ecommerce Order Fulfillment Processes?

While all ecommerce companies are different, there are some basic steps that all brands will take in the fulfillment process, and each of these steps will impact how the store owners will manage their inventory.

Understanding these steps is important to modify the fulfillment journey to suit your business.

Let’s quickly look at the different steps.

1. The customer places an order

Before the customer can place an order, they must be able to tell if stock is available in their location. Otherwise, they might place an order and pay, but the order will never arrive.

2. Receiving an order

Once the order is placed, the order needs to be sent to the warehouse. This process is usually automated, so the warehouse receives the order without the store owner needing to push the order himself. However, if you are a small startup selling on an ecommerce platform like Etsy or eBay, you may be processing the order yourself.

3. Picking and packing

Once the order has been sent to the warehouse, it's time to pick and pack.

First, the team must find the item on the shelf. This is called “Picking.” The way they find the inventory is usually through a barcode system.

The second step in the warehouse is called “Packing,” and this is the step where the team puts the product into the packaging with the packing slip ready to be shipped to the customer.

4. Shipping

Shipping is usually outsourced to a third party, such as FedEx, USPS, UPS, or another shipping company.

If you are using a third-party logistics provider, then the warehouse will ideally need to be able to integrate with the shipping company so that the shipping label can be printed before being handed over and the shipping costs and delivery times can be displayed transparently to the customer at the checkout.

5. Returns and customer service

Returns are an unfortunate yet inevitable part of ecommerce fulfillment operations. You must give just as much attention to your returns process as you do your shipping process, as a good returns process can improve your sales and profitability.

The customer experience is important, and a great returns process will give great customer satisfaction.

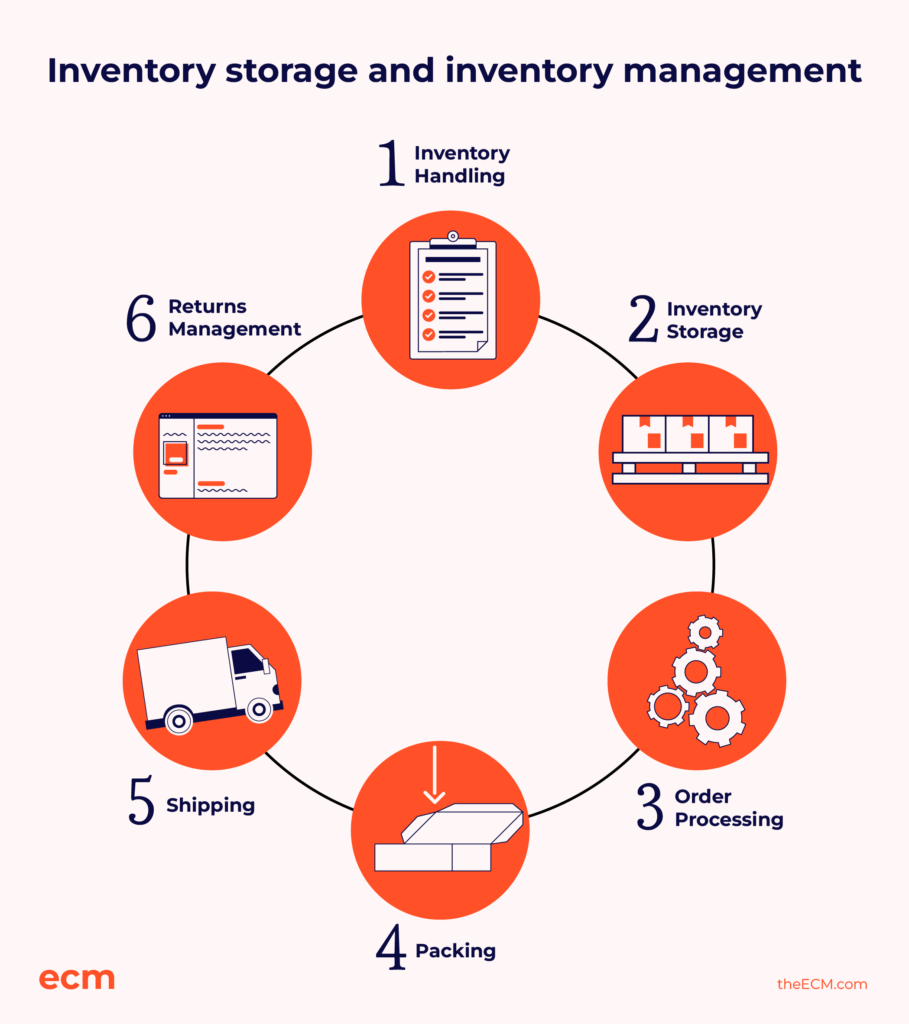

6. Inventory storage and inventory management

Keeping your products in good condition and keeping track of stock movements is vital for your order fulfillment, as it impacts every part of the fulfillment process.

If you don’t know how much stock you have, your customers might be disappointed when they order a product that is out of stock. It is important always to give a good experience as customer expectations are always high.

Different Types of Order Fulfillment

There are five main types of order fulfillment, and each fulfillment option will have a different impact on how you manage inventory.

In-house fulfillment

This is when you manage all aspects of the fulfillment journey in-house. For very big brands, the whole journey, including the last-mile delivery, can be done in-house. For small businesses, this is sometimes called self-fulfillment. One of the advantages of an in-house order fulfillment strategy is that you have full control over the whole process, and you can save money.

However, consider how much additional stress could be caused by managing a new team. I worked on a huge warehouse implementation for a large UK-based fashion brand, and the move to a new system caused a lot of internal headaches!

Third-party order fulfillment

Third-party fulfillment is when you outsource the process, including warehousing and shipping. Some services offer full-service outsourced fulfillment, and some allow you to pick and choose which services you want to use. This is a great guide to the best 3PL companies you can use for your ecommerce business.

Marketplace fulfillment

Many ecommerce brands outsource their order fulfillment service to a marketplace such as Amazon FBA. The best thing about this is your customers get easy access to your products, and they get next-day or sometimes even same-day shipping options, which is a great customer experience.

However, it can be more expensive than making sales from your site, affecting your bottom line. FBA isn’t necessarily the most cost-effective, but it can be a great way to gain a new customer base and make a large number of sales.

Dropshipping order fulfillment

Dropshipping as an order fulfillment model had a bad reputation, as people shipped rubbish products straight from AliExpress. Now, however, there is a trend of dropshipping ecommerce brands shipping quality products from local sellers. Shopify has launched dropshipping plug-ins for your site, making it even easier to work with dropshipping suppliers. Using an ecommerce platform for dropshipping is as simple as installing a plugin, so long as your paid plan allows for such.

Hybrid fulfillment

While all of the above fulfillment methods have pros and cons, in practice, most ecommerce retailers use a mixture of all the above methods. In my business, I started selling on Amazon FBA but quickly moved to fulfill my customer orders from other channels via a 3PL shipper.

How To Use Order Fulfillment To Manage Ecommerce Inventory

Having a good order fulfillment process is the most important way to keep on top of your ecommerce inventory. Here are the 6 best practices for using your order fulfillment process to manage your commerce inventory.

Automate your processes

The most important process to automate is the order going directly from the point of sale to the warehouse for picking and packing. By automating this process, the warehouse can pick and pack the product immediately, which means that the inventory can be kept up to date in real time. Pick and pack software is one of the ways you can achieve full automation.

Integrate your systems

Your inventory management system, order management system, customer services, and warehouse management systems (WMS) must show accurate data to manage your inventory effectively and help with order volume forecasting. If the customer sees a product in stock, but in reality, it is out of stock, then they are going to get a very bad experience. By integrating all your systems or using an ERP, your customers and team members will know exactly how much stock there is, where it is, and important data, such as shipping times.

Change your packaging

Packaging has a massive impact on your order fulfillment for a number of reasons.

If your packaging is too large, it will take up more space in the warehouse and cost more in shipping.

When the packaging isn’t safe enough, you will get more returns, which will impact your profit margin and also take up more space and resources managing the inventory when it is returned.

Consider reworking your packaging to keep your products secure while minimizing excess space to save money.

Make returns easy for your customers

Some companies make product returns complicated because they don’t want customers to send products back. But this is very shortsighted, as most customers now look at the returns policy before they make a sale.

A great returns process also helps your inventory management, as your products are much more likely to be returned in a sellable condition.

Have good data reporting

If you have a well-integrated fulfillment system, you should be able to report on inventory data accurately. This is important for inventory planning as it helps you restock the correct amount for different times of the year.

For example, you might find that if you sell beach clothes, your data will probably show that you sell more in June-August, which will help you order the correct amount of inventory for the right time of year.

Organize the stock in your warehouse

Warehouse space is expensive. If you have some core items which sell quickly, then it will help your inventory management workflow if that stock is placed near the front of the warehouse so it is easy to be picked. If you have stock in many different warehouse locations, it can be very time-consuming to keep going to different corners of the warehouse to find stock.

At the big UK fashion retailer, we placed underwear near the pickers as customers often added underwear and socks as an add-on in the basket. This saved a huge amount of time for the warehouse staff and helped us to manage the inventory effectively.

Order Fulfillment + Inventory Management = Happy Customers

The order fulfillment process has a big impact on how you manage your inventory, as it is one of the main moving parts of your business.

When your inventory is moving around to different locations and being stored in multiple warehouses, it can be hard to keep on top of it. The most important thing to do is to ensure your systems are integrated, and you have good processes in your business to manage your inventory and deliver products to your customers safely and on time.

For more order fulfillment and inventory management tips and advice, subscribe to The Ecomm Manager newsletter today.

More great ECM content:

- A Guide To The Global Order Fulfillment Process

- What Is Ecommerce Inventory Management? And How To Get It Right

- What Is Pick And Pack In Order Fulfillment?

- How Does Dropshipping Work? Pros & Cons + Tips To Get Started

- Ecommerce Returns Best Practices: How To Handle & Solutions (Guide)

ECM recommends: