In 2022, over $420 billion of products were returned to the seller, representing around 10% of all online sales that had to be handled through the reverse logistics process.

However, this statistic is pretty much meaningless by itself, as it includes ALL industries and categories online. Clothes and accessories, for example, have a return rate of around 16%, whereas health and beauty have a return rate of just 1%. What these statistics do show, however, is how important it is to understand your reverse logistics process. Not only can they take up a big chunk of your turnover, but they can be entirely different for different industries.

On top of these returns rates, less than half of returned products can be resold at full price, and the method of return logistics is at least partially to blame for the quality of the products when they land back in your warehouse.

In this guide, I’ll go through the reverse logistics process, best practices, and some practical tips you can use in your business to improve your processes, impress your customers, and save money.

What Is Reverse Logistics?

Reverse logistics is the nuts and bolts of the ecommerce returns process. If a customer needs to send a product back to you for any reason, then reverse logistics are what will get the products back to you safe and sound.

Efficient reverse logistics start from the moment a customer decides they want to send their product back. Before they have even handed the product over to the post office, the reverse logistics process, or reverse supply chain, starts with your return policy.

The returns management process includes the shipping of the products, the handling of the products in the warehouse, the warehouse management system, the customer tracking updates, and the quality inspections.

Essentially, it includes any process that is involved, from the customer deciding to send something back to you receiving the item and reselling it or disposing of it.

Why Are Return Logistics So Important?

There are two main reasons why returns logistics are crucial.

The obvious one is to save you money as a retailer by getting the products back to you in a sellable condition. But the second reason is that customers are much more likely to buy from a company that has a reliable and transparent returns process, and the logistics are a huge part of that.

In my previous article on ecommerce returns, we discovered that 60% of customers look at a returns policy before making a purchase, and 27% of customers are more likely to buy a product if they can return it for free. That is a lot of potential customers you don’t want to miss out on, showing the importance of the customer experience.

Loyal customers are much more likely to be repeat customers, and repeat customers are cheaper than acquiring new customers. Customer loyalty is the holy grail of online business, so ensuring customers have a great return experience is essential.

In summary, having an effective reverse logistics process is a really important part of your overall ecommerce strategy. If you ignore it, you will lose customers in the long run.

How Reverse Logistics Works

Reverse logistics in ecommerce are different from traditional logistics in that the person starting the whole process isn’t the point of origin, manufacturer, distributor, warehouse, or business but the customer.

This means there can’t be a very technical system to start the returns logistics operation, as the customer won’t know how to use it, mistakes will be made, and you will lose money.

There are also different types of reverse logistics, depending on your overall business model.

Let’s have a look at how the returns logistics work and some best practices.

The reverse logistics process

Depending on what industry your ecommerce brand is in, the reverse logistics management might look slightly different. Having an excellent reverse logistics plan before you create your policy is the best way to start.

For example, if your products are fashion products, your reverse logistics process will be relatively straightforward. The primary consideration you want to make is whether you offer free returns, how the products can arrive in a resealable condition, and what sort of quality inspections you will make to ensure the return is genuinely unworn or unused.

However, if your company sells food in recyclable packaging, you might want to consider how a customer will send back a product without it going bad, the packaging breaking, or even whether they need to send the product back at all.

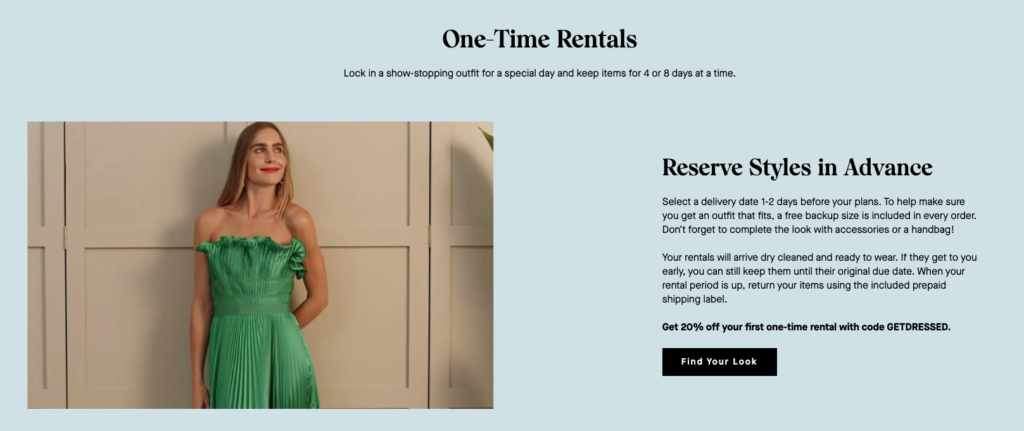

Some ecommerce businesses also might need to get the products back to them as part of their overall business model—for example, if your ecommerce brand hires or rents the products or parts of the products.

Rent the Runway, a fashion brand that allows you to borrow designer-label clothing, sends you the products with a pre-paid postage bag so you can simply post the products back to the warehouse:

How To Build A Great Reverse Logistics Process

Before you dive straight into working with a logistics company, you need to have an understanding of how your reverse logistics process will work. The reverse logistics process is just one part of your logistics supply chain, so it needs to fit in with your logistics business model.

1. Outlining your returns policy

We covered the returns policy quite thoroughly in my previous article about ecommerce customer returns. Still, the most important thing is that the policy is clear, and the customer understands exactly what they need to do to return a product. The returns logistics process is kicked off by the customer deciding to return the product, so making the policy as straightforward as possible is vital to building customer trust.

2. Initiating customer returns

Once the customer has decided to return a product, they need to initiate the return. For some brands, it makes sense for the customer to contact the customer service team to initiate the transfer. This is how Amazon usually handles returns because they have so many different kinds of products, often sold by third parties, that there isn’t an entirely uniform returns process.

Other brands, such as Asos, allow you to send products back with a prepaid package. This is the most convenient process, as customers can simply send the products back, and there is no charge. Some of the bigger logistics services, such as UPS, Royal Mail, and DPD, offer services for pre-paid returns, so you can compare which service will work best for you.

Another returns process could include the customer scanning a QR code which allows them to simply return the parcel to a drop-off point.

Whichever method you choose, you should make sure that the returns initiation is integrated with your overall inventory management software.

3. Processing the return

Once the customer has initiated the return, you need to accept or deny the return. For most businesses, the return would be automatically accepted if it is within the allowed timeframe.

However, a product may be accepted if it is faulty or there is a different issue. You could also initiate an exchange during this process, as a customer may simply want a different size or color. You don’t want to lose the sale if you can avoid it, so offering an exchange or store credit is a great option.

4. Receiving the returned items

If the return has been accepted, then you need to receive the item back at your warehouse. Some of the leading logistics partners will integrate with your overall order management system, so you will know the product is on its way. The best systems also allow the customers to track the return.

When the item arrives at your warehouse or distribution center, you will need to inspect the product for quality and also to make sure the stated return reason matches the returned item. Some customers lie about the reason they have returned goods, and you might want to take action against repeat offenders.

This inspection is also to check if the item is still in a sellable condition or if it needs to be recycled, fixed, sold as refurbished, destroyed, given to charity, or disposed of in a way that works for your business.

If the item can’t be resold, then it may need proper disposal or refurbishing so it can be given away.

Some third-party warehouses will do these processes for you, and they may use repackaging for resellable goods or break items down into their raw materials so they can be reused.

Related articles:

- How Recommerce Helps Make A Difference For Your Brand And Customers

- The Sustainable Ecommerce Guide To Dead Stock

How To Use Reverse Logistics To Improve Your Business Performance

Reverse logistics aren’t just about getting the products back to you in a sellable condition. You can also use them to get critical data about your products, improve customer retention and reduce your costs.

Use reverse logistics to understand your customers

By having a solid reverse logistics process, you can start to understand your customers better by understanding why they are returning products. For example, you may notice that a particular color variation is being returned more often. Real-time data like this can help you to plan future product releases.

Use reverse logistics to improve your product offering

When you understand the reason that customers are returning products, you can start to understand how you can improve your products or processes.

For example, if a product is being returned broken, you may need to improve your packaging, or if a product is being returned because delivery was late, you may want to improve your warehouse and logistics process.

Use reverse logistics to reduce losses

If a returned product isn’t sellable, you will be losing money which will affect your bottom line. A lot of brands have a resale department, where customers can buy slightly damaged products on the secondary market.

By understanding return reasons, collecting customer data, and optimization of your processes and product offering, you can reduce the returns in the future.

Another way you can reduce losses is by incorporating a good inspection process into your reverse logistics. This can return more products to the shelves or increase the number of products you can recycle or reuse, rather than sending lots of trash to the landfill. This is also good for your sustainability image, which helps to improve your brand’s reputation further.

Use reverse logistics to reduce costs

Storage can be one of the most expensive aspects of your business, and understanding returns can help you to optimize your storage space. Returns need to be stored, and understanding returns can also help you to be cost-effective in ordering the right amount of products for a new product release.

If you are using a 3PL as part of your supply chain management and you are outsourcing to logistics providers, then returns costs will need to be factored in, and different companies have different prices for returns from different regions.

By understanding your ideal reverse logistics system, you can make sure you are paying the right price for these outsourced services.

Fraudulent returns are a big problem and can cost a lot of money. By having a good inspection process within your reverse logistics procedures, you can reduce the amount of money you lose to bad returns and stay on top of bad customers.

Reverse logistics improve your brand’s reputation and customer retention

As we have already discussed, returns are a huge part of the customer decision-making process. A good reverse logistics process will encourage more customers to shop with you and also help your existing customers to buy from you again.

Knowing that your products are easy to return will give customers the confidence to buy from you, knowing that your excellent service will allow them to return anything that wasn’t quite right. More importantly, a customer is more likely to return something in a sellable condition when they appreciate the excellent service.

Customer satisfaction is key if you plan on scaling the business.

Don’t Lose It, Reverse It

Reverse logistics is just one part of your overall supply chain process but is often overlooked.

No business wants to think about refunds, but by having an efficient process in place, you can not only reduce returns but improve your bottom line overall. When you are thinking about your own reverse logistics process, make sure you think about your products and what an ideal process would look like.

Once you know what your ideal process is, you can start to outsource the logistics and integrate it into your overall order management system.

For more essential ecommerce logistics tips and strategies, subscribe to The Ecomm Manager newsletter today!

More great ECM content:

- Ecommerce Returns Best Practices: How To Handle & Solutions (Guide)

- A Guide To The Global Order Fulfillment Process

- Ecommerce Warehouse Process Guide: Expert Tips & Advice for Success

- Ecommerce Shipment Tracking: How To Use Order Tracking To Boost Your Sales

- 10 Best Order Management Software

- 10 Best Order Tracking Software For Online Stores

- 10 Best Warehouse Management Software