Imagine your current warehouse layout where it takes ages to find any products, you never know how much inventory you have and shipping is often delayed.

This is often down to the design of the warehouse, and the knock on effects of a bad layout are lost customers.

In fact, the layout of your warehouse can improve efficiency by up to 75%, yet many warehouses don’t have any real systems in place for optimizing their layout.

In this guide, we’ll go through some common warehouse layouts, and give you some actionable tips to design a layout that works for your warehouse, whatever its size.

What is Warehouse Layout Design?

Warehouse layout design covers the floor space of the warehouse, the use of the vertical space, and the storage solutions such as storage bins and pallet racks.

One of the most important aspects of a warehouse for ecommerce brands is how efficient it is for your warehouse team to pick and pack items to get out the door fast.

The physical design and layout of the shelves, shipping area, and storage areas has a huge impact.

Even a small difference in warehouse design can have a big impact on the supply chain and bottom line.

Say each warehouse worker picks and packs 100 SKUs a day. What happens when a bad layout adds an extra 20 steps per SKU? That’s 2,000 extra steps per employee!

While good for their fitness tracker, you can see how this doesn’t scale up efficiently and ends up causing increased staffing costs and shrinking profit.

The floor plan of the warehouse is the main feature of warehouse layout design. However, it isn’t limited to the layout of the shelves.

It includes the height of the shelves, the types of products you are storing, the equipment and technology you will need, and the number of employees needed to manage it all.

Why is warehouse design important?

A good warehouse design has an impact on almost all parts of an ecommerce business, from inventory management to order fulfillment.

Improving overall efficiency is the main benefit, but there are three other benefits to a good warehouse design.

1. Reduced operational costs

Small changes in the layout can bring big reductions in costs, as many changes can have knock on effects for other tasks, improving the efficiency of the warehouse and the staff.

- Streamlined operations. A well-planned warehouse layout minimizes unnecessary movements, cutting picking and packing time and labor costs.

- Energy efficiency. Reduce energy consumption and the use of expensive equipment, such as forklifts, with optimized travel paths and equipment use.

- Optimized storage space usage. Maximize storage capacity and reduce the need for additional facilities.

2. Improved employee productivity

Staff want to work in a warehouse that is safe and productive. Plus, they want a workplace environment that can help to further their careers.

- Ergonomic design. Increase worker comfort and reduce physical strain, by limiting things like lifting and moving heavy stock.

- Reduced picking time. Logical inventory organization speeds up picking and accuracy. Storing faster-moving items nearer the packing station will make a big difference.

- Amazing staff training. Simplify onboarding new staff, helping new employees become productive faster.

- A great warehouse management system (WMS). This speaks for itself, use the technology to help your staff, not make their life harder.

3. Enhanced safety

Safety needs to be your number one concern in a warehouse. Safe warehouses are generally more productive too.

- Clear traffic lanes. Designating specific areas for activities reduces accident risks. Less clutter also reduces the risk of tripping.

- Clear safety procedures. Different warehouses have different needs, such as chemical safety, falling objects, heavy machinery amongst other risks. A good layout will help reduce these risks.

What Are The Different Types of Warehouse Design Layouts?

I have seen three main types of warehouse layouts in small to medium-sized ecommerce warehouses, and each has its own benefits.

Huge warehouses, such as Amazon or big 3PL warehouses, may have their own shapes and systems, but I am focusing on normal warehouses for most ecommerce brands.

For most businesses, the shape of the building will determine what shape you go for, but if you have the freedom to choose the design, there are benefits to each of the different warehouse shapes.

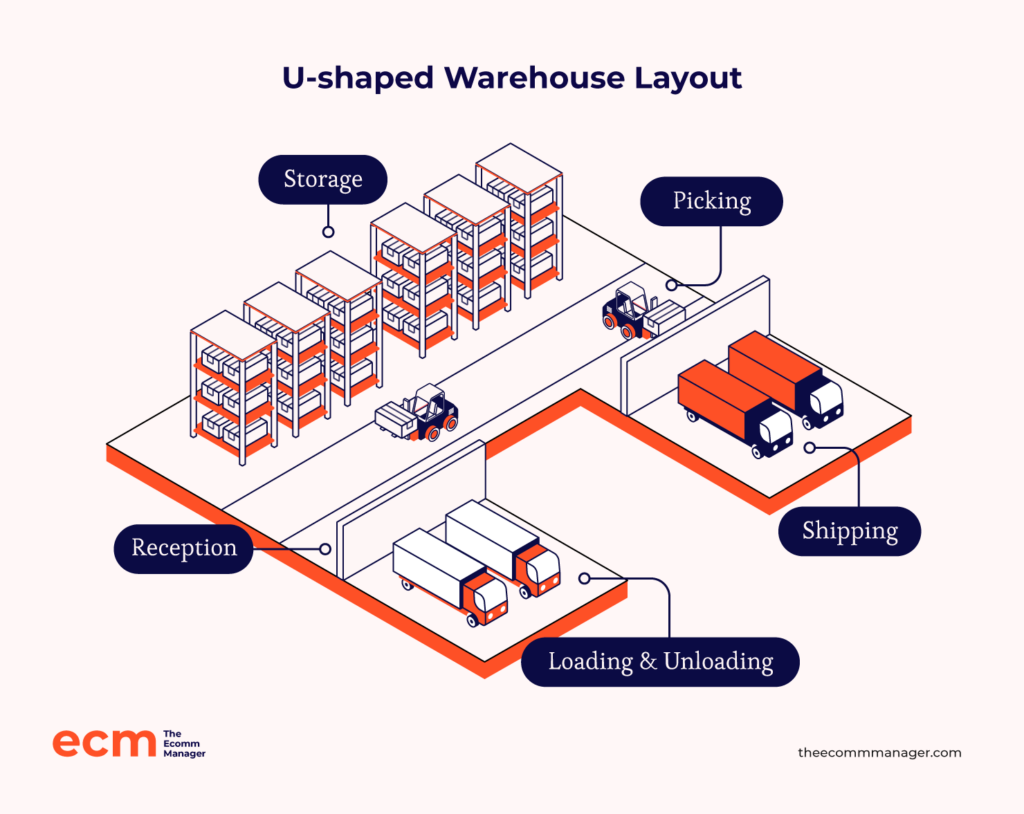

U-shaped warehouse layout

These semicircular warehouses have the inventory stored at the back with the loading bay and packing area at the front with a separate entrance/exit for each.

Who is this warehouse design best suited for?

The U-shaped design is suitable for all sizes of warehouses, and it is probably the most common type of warehouse operation.

The design also fits in a nice square shape, which suits most buildings.

Benefits and drawbacks

- 👍 Great use of space. This warehouse maximizes a space so you can store a lot of inventory.

- 👍 Easy picking and packing. It is easy to place fast moving items at the front of the warehouse, so they can be picked and packed easily.

- 👎 Requires more space. Generally, this warehouse design would need its own building, so it is only suitable for businesses with their own dedicated entrance and exit.

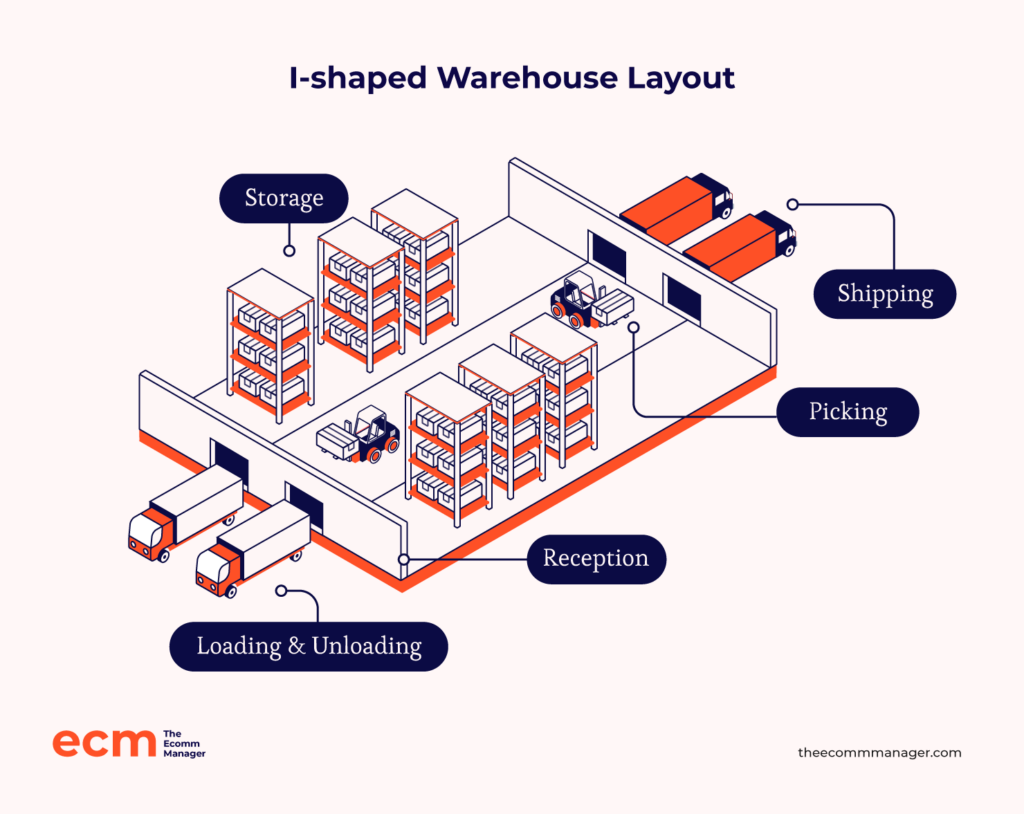

I-shaped warehouse layout

The I-shaped warehouse, or through-flow design warehouse, is designed in a line, with the entrance at one end and the loading bay exit at the other. The inventory is stored in the middle.

Who is this warehouse design best suited for?

This is suitable for companies with fast-moving throughput, such as fashion brands.

This is because the constant flow of trucks won’t get in each other’s way, and the streamline design of the warehouse allows for a production line style of operation.

Benefits and drawbacks

- 👍 Speedy picking and packing. This is a great design for a production line style of picking and packing, as it is easy for staff and machinery to keep to their zone.

- 👍 Good for zonal picking. It is easy to place staff in picking zones, as they could have a row of shelves each.

- 👍 Easy to share a warehouse space. It is easy to share this design of warehousing with other businesses, as you can split the warehouse in half.

- 👎 More space required. You will need parking areas for incoming and outgoing trucks, so you may need a larger site.

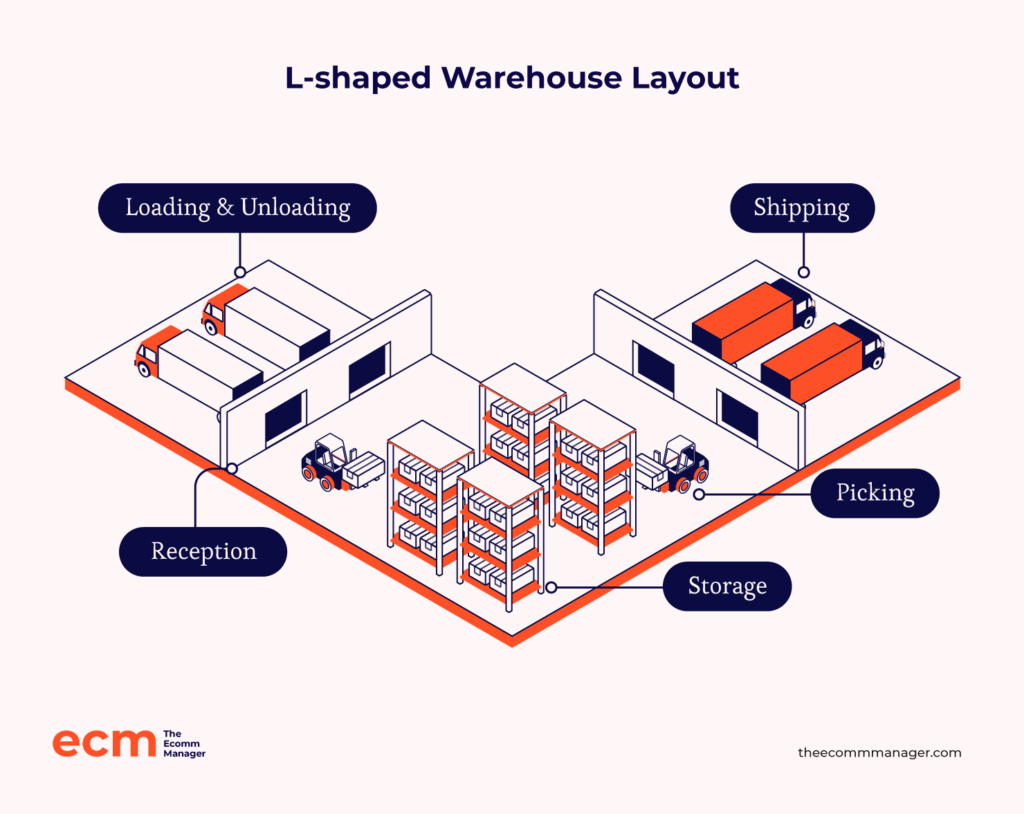

L-shaped warehouse layout

This design is usually found in the corner of a warehouse.

L-shaped warehouses are a common feature in 3PLs, distribution centers, and warehouses that are shared between multiple businesses.

This shape warehouse is also used for businesses that occupy their own warehouse fully, but are restricted on the space because of the shape of the building or the site.

Who is this warehouse design best suited for?

L-shaped warehouses are ideal for mixed use ecommerce brands that have a mixture of fast moving and bulk storage items.

It’s also a good use of space in shared warehouses, as you can give each business a corner to use.

Benefits and Drawbacks

- 👍 Flexible shape. This design is great for businesses who need to be flexible with the warehouse shape they use.

- 👍 Easy zoning. It is easy to zone different types of products in different areas, for example placing bulk storage nearer the corner and fast-moving items next to the packing area.

- 👎 Complicated set up. This style of warehouse might require more systems to be put in place for the movement of staff and machinery, especially if you are sharing a warehouse.

Key Considerations For Warehouse Layout Design

Each business is different, and there are many things that will affect your decision of warehouse design.

The main thing to consider is your available space and budget, as it will impact any decision you make. Let’s have a look at some questions you can ask to make smart decisions.

What do you sell?

The type of products you sell are important, as it influences where you will be storing products.

You need easy access to fast-moving products, and bulk storage products need to be kept safe but out of the way.

If you sell a single type of product, then your layout will be different from multiple product operations.

For example, a fashion brand will store products that can be picked by hand, but if that fashion brand also sells larger homewares, you may need a forklift to pick products.

When I designed the warehouse layout for a UK fashion brand, nearly all the stock was picked by hand, and it was often kept in storage bins rather than shelves.

The only time a forklift was used was for receiving items, and adding/removing them from the storage area to the order picking area.

This will impact the design of the warehouse, as my design wouldn’t work for a warehouse specializing in storing washing machines and tumble dryers.

Certain products also have special requirements.

For example, products that require refrigeration, fragile products, or chemical products all have very different requirements and even different laws.

What is your workflow?

There are 4 main picking strategies, and each will have a different warehouse workflow:

- Discrete picking. Each order is picked individually.

- Batch picking. Multiple orders are picked at the same time to minimize trips.

- Zone picking. A warehouse is divided into zones, and pickers are assigned to specific areas.

- Wave picking. Combines elements of batch and zone picking, organizing picks based on similar shipping times or destinations.

The type of picking you use in your business will impact the way you layout the warehouse.

For example, if you use zone picking, it makes more sense to use L shape or U shape designs, as they give you more flexibility in where you place the zones.

Your existing warehouse space

Unless you have the luxury of designing a warehouse from scratch, you will need to work with the space you have been given.

Some warehouses can have products stored on high shelves, with a forklift truck picking most items, whereas others will have everything on the ground floor.

If you are using zones, then use the existing space to dictate where your zones go.

Fast moving items should be near the picking station, where they can be picked the fastest. Slower moving items can go higher up on shelves, or further away from the picking station.

The warehouse space will dictate whether you can keep items on high shelves or not.

Think about how the trucks will enter and exit the space, too, as you don’t want congestion or traffic safety issues.

Space is the most valuable asset in a warehouse, so you want to use as much of it as possible.

Your equipment

Shelves, racks, and storage boxes come in a huge variety of shapes, and they can usually be customized to fit with your warehouse space.

But some equipment such as carousels usually come in set sizes.

Space must be allocated for operating large machinery like forklifts and pallet jacks safely.

Some things you need to consider are aisle widths, turning radius, and loading dock access. Measure the equipment you already have, and add these to your warehouse plan.

Forklift trucks have special requirements for aisle width, and generally your aisles should be at least 12 feet wide if you have pallet loaded forklifts.

Your warehouse zones

There are five key areas that you need to add to your warehouse plan: receiving, shipping, outbound packing, storage and office.

The areas need to be laid out according to your warehouse space and the zones you want to use.

It needs to be easy to move between areas, and it should be clear for staff members to know how to know where they are going, as this will make it more efficient for your staff.

Your budget

Before you blow the budget buying expensive equipment, make sure you work out what the best ROI will be for the warehouse.

Focus on equipment that will improve picking efficiency and reduce labor costs, as these will have the biggest ROI compared to a fancy new forklift.

Other equipment that can be expensive is refitting or redesigning a warehouse.

New shelving, for example, can be expensive to install, so it might be a good idea to consider how you can best make use of your current space and equipment.

If you need to fully refit or resign the warehouse, you might need to use consultants, or even architects, to design the space effectively.

But you can generally make savings by iterating or updating your warehouse when you need to.

Safety regulations

Each country will have different regulations, so you should do your own research, but these are the most important safety concerns you need to factor into your plan:

- Slip, trip, and fall hazards. Uneven surfaces, narrow pathways, or obstacles in walkways.

- Forklift and vehicle accidents. Collisions, overturns, or improper operation.

- Falling objects and load collapse. Due to improperly secured materials or overloading.

- Fire safety measures. Including fire exits, fire extinguishers, and sprinkler systems.

- Chemical and hazardous material spills. Correct storage or handling

- Quality control. Improper safety practices can impact the end products through spillages and other accidents.

There are other safety considerations, and the Occupational Safety and Health Administration (OSHA) provides guidelines and resources for warehouse safety in the USA.

There are also certifications your safety team can do.

8 Steps For Designing An Efficient Warehouse Layout

Before you design a new efficient warehouse layout, you should consider the current bottlenecks you are facing.

Your staff may be complaining about a particular bottleneck or traffic jam, and these will be the first areas to address when you create the new warehouse layout.

Once you understand any current bottlenecks, you can start to plan for the new warehouse.

Step 1: Understand the main warehouse zones based on workflow and space

The main zones you need to consider are receiving, storage, picking, packing, shipping, and return processing areas.

You need to think about where these areas are going to be placed in the warehouse, who is going to be using each area and the flow of goods through each area.

Once you have understood all the functions, you can think about the space needed for the flow of people, machinery, and materials.

Start sketching out ideas of how these flows might work ahead of mapping out options.

Step 2: Map out potential layouts

If this is your first time mapping out a warehouse design, you could use some software to help you out.

Some of the best warehouse management software tools have warehouse layouts in them, but you can also use design software or even grid paper and pen.

Your final design could look something like this:

Step 3: Plan your storage options

We have been through the different types of products that will have different storage needs.

The main things to consider are whether you will be using bins or shelves. Larger items probably need shelves or secure storage systems, whereas clothing can go in bins.

Will products stay on pallets, or will they be sorted into different areas?

Sometimes a brand might need both options for the same SKU. For example, a fashion brand that sells D2C and wholesale will probably have some products sorted into their categories and some remaining in boxes on pallets ready for bulk shipment.

As we’ve discussed, the product you sell and what channels you sell on will deeply affect your storage options.

Step 4: Choose your equipment

Assess your material handling equipment needs.

There are many types of equipment to move stock around, such as basic pallet jacks and forklifts to more advanced systems like carousels and conveyors.

While equipment can improve efficiency, it also takes up space and they can be quite expensive.

For example, forklifts require wider aisles than pallet jacks, reducing overall storage capacity. Plus, they are very expensive.

But, if your warehouse is tall, and you are appropriately utilizing that space, there’s no better option than a forklift to store and pick those high SKUs.

Step 5: Map out your design in the warehouse and do a walkthrough

Once you have mapped out your warehouse either on paper, or using software, you can then go to the warehouse to test how it looks and performs in person.

When I designed the warehouse for a UK fashion brand, we used masking tape on the warehouse floor to mark out the shelves and practice the workflow.

It also gave a nice visualization of the space.

This way we could work out if the plan worked in the physical space, and the equipment would all fit. This was time-consuming, but worth it, as it meant any issues and inefficiencies were ironed out.

We also got the warehouse staff involved in this stage, so we could see any pain points they might struggle with.

The warehouse management system is the machine that powers your warehouse, and you can add your layout into the system, so it can help staff find items and help you keep a track of inventory.

Step 6: Plan for growth

One of the main benefits of using a 3PL is that they can often scale with you as your business grows.

When you have your own warehouse, this is a challenge, as you are limited in the amount of space you have.

Some areas are easy to expand, such as adding more shelves, but you may need to consider having a more flexible storage area, so you can store more items.

Make sure you create enough space for loading and unloading, as when you grow you will need more trucks.

Many growing warehouses use an inventory management technique called just-in-time (JIT).

The benefit of just-in-time is you order inventory or materials on an as-needed basis, which means you require less inventory in the warehouse storage.

The benefit of this system is you don’t over order inventory, there is less waste and you can reduce storage costs.

The downside is you need reliable reporting to forecast customer demand, and you're a reliant on your suppliers buying in to your process.

Most bigger companies use a mixture of Just In Time warehouse management and bulk ordering stock.

Step 7: Choose your technology

The warehouse is one part of your overall order management process, so you need to choose a warehouse management system (WMS) that integrates with your current systems.

You also want to use technology that isn’t too expensive and can scale with you as you grow.

The best order management systems (OMS), ecommerce platforms, enterprise resource planners (ERP) and inventory management systems all integrate easily with the best warehouse management systems, but check integrations and features before you purchase.

All WMS include some level of automation and real time data tracking, but the more advanced solutions have a wider range of integrations.

Check out The Ecomm Manager’s top ten picks for warehouse management software:

Step 8: Continuous improvement

Choose the KPIs you are going to track for warehouse optimization, to manage the performance and keep making improvements to the design.

Your WMS will likely be able to help you with this. The best ones have data systems built into the dashboard.

Each business is different, but some of the main KPIs I have tracked before are:

- Order fulfillment time: The time from order placed to shipped

- Picking accuracy: The percentage of orders that are picked correctly

- Space utilization: This measures how effectively you are using the space you have. This could be a manual check or your WMS can track it.

- Staff productivity: You can measure how well the new system is working by measuring stats like, number of units picked per staff member per hour.

Design a More Productive Warehouse Layout

The warehouse layout has a big impact on the efficiency of the order process.

Improving the efficiency will mean you can pick more items and make more sales. You can also save money on staffing costs and have a happier and more effective team.

The layout can be a big job to change, but it is one of the best things you can do to create a safe and efficient workplace.

A new warehouse layout, with automated integrations on your warehouse management system, will have a massive impact on your warehouse.

You will see the changes quite quickly by following these steps and reporting on the right KPIs to keep you on track.

For more information about warehouse management software, check out this guide with some of my favorite software, and the pros and cons of each.

The world of ecommerce moves fast—and so do you. Subscribe to our newsletter with the latest insights for ecommerce managers from leading experts in ecomm.

Warehouse Design FAQs

Before we sign off, let’s get some final questions and answers in on this topic.

What is the most common warehouse layout?

The most common layout is the U shaped warehouse, as it is a great use of space.

However, this space warehouse only works well if you have your own dedicated building. If you are sharing a warehouse with other brands, you will probably need an L shape or I shape.

What is the best layout for a small warehouse?

Small warehouses need to use the space they have as effectively as possible. The shape of a small warehouse is less important than the use of vertical space, as you will need to take advantage of the height of the warehouse.

You should also make your storage area and slow moving items area, as tightly packed as possible to keep more space for faster selling stock.

What are the main areas of a warehouse?

The main areas are reception, packing, shelving, storage, storage, entry and exit docks and office.

How do I fix my warehouse layout?

Start by making a plan of the warehouse you currently have, and mark out the different areas or zones.

Now look at how you are using the space you have available and how effectively you are using the space. If the stock is taking a long time to be picked and packed, you might have a problem with where the stock is stored.

Consider moving faster moving items to nearer the picking station and slower moving items can be moved higher up shelves, or into storage.

Once you have identified these problems you can change your warehouse layout to suit your needs.